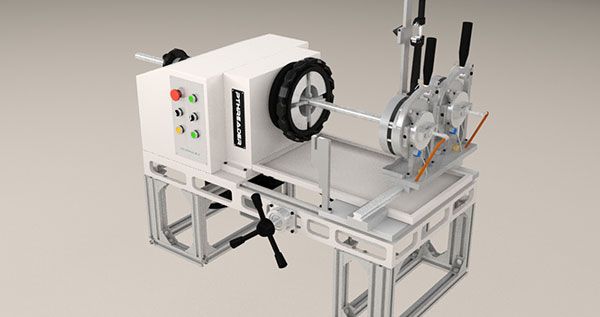

Thread rolling is a metalworking process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Rolling reduces the blank's diameter and produces a concave thread with sharp edges on one or both sides of the thread. The rolling process is repeated many times until the desired shape and profile is achieved.

It is done through multiple attachments on a lath machine. The high pressure from the thread rolls causes the metal material to flow outward into the cavity between the thread rolls. This produces thread geometry that looks like that of an rolls.

This is a new process of forging metal forging process that forms threads into a roller die. This process is used as an alternative to metal cutting and metal grind because it does not remove any metal part from it piece but rather improve and mold upon it.

The main advantages of this type of process is:

• Strength

• Accuracy

• Economy

• fine surface finish