Having an efficient plumbing system that prevents leakage is vital for any household. Pipe fittings are affixed to the end of pipes to facilitate directional change, flow control, and pipe diameter adjustment. As pipe fittings are a crucial component of plumbing and piping systems, it is essential to know about various plumbing network components. We will discuss a critical component of a plumbing system called the pipe nipple and why you should use the highest quality of this component to make your plumbing long-lasting.

A pipe nipple is an essential type of pipe fitting used to connect two pipes or hoses in a plumbing system. A pipe nipple is threaded at both ends to connect the two long pipes and make a waterproof seal. The pipe threading is called male pipe thread (MPT), which fits a female thread of the two pipes that are to be connected by the nipple. This ensures the continuity of the plumbing system without any leakage. Pipe nipples are available in various materials, such as brass, aluminum, plastic, etc. Plumbing systems are an essential part of households as well as industries. No plumbing system is complete without pipe nipples. Some industries that utilize plumbing systems include waste management, chemical, food and beverage, machine building, paper, etc.

If you are purchasing pipe nipples, there are several factors that you should take into account. The initial consideration is the tubing selection, which encompasses the material, thickness, and diameter. Additionally, it's essential to know the general specifications, such as temperature and pressure ratings and safety coefficients. Lastly, understanding the end connections is crucial, which includes knowing the type of connections, such as threads, square cut, grooved, beveled, bent, barbed, or seamless.

It is crucial to understand the galvanization process to see the benefits of galvanized pipe fittings. Galvanizing a pipe involves adding a protective coat of zinc metal to any steel or iron to prevent rust. Galvanization is a cost-effective method for steel protection and strengthening, and galvanized steel is widely used in the construction industry to make durable steel structures like building frameworks, balconies, staircases, walkways, and much more. By the early 20th century, galvanized pipes had become widespread and replaced cast iron and lead in household plumbing systems. The most commonly used galvanization process is hot-dip galvanizing.

Step 1: The steel is washed with an alkaline solution to remove surface dirt, paint, and grease.

Step 2: After rinsing off the alkaline solution, the steel is dipped in an acidic solution. This smoothens the surface of steel by getting rid of iron oxides.

Step 3: After rinsing off the acidic wash, the zinc ammonium chloride protection layer is added to the steel to slow the rusting process. The layer is allowed to dry on the steel.

Step 4: The steel is immersed in molten zinc until the steel temperature becomes the same as molten zinc. Lead is added to the molten zinc to make molten zinc more fluid and thinner.

Step 5: Rapid steel cooling uses a quench tank to prevent any unnecessary reaction of the protective zinc coating with the atmosphere.

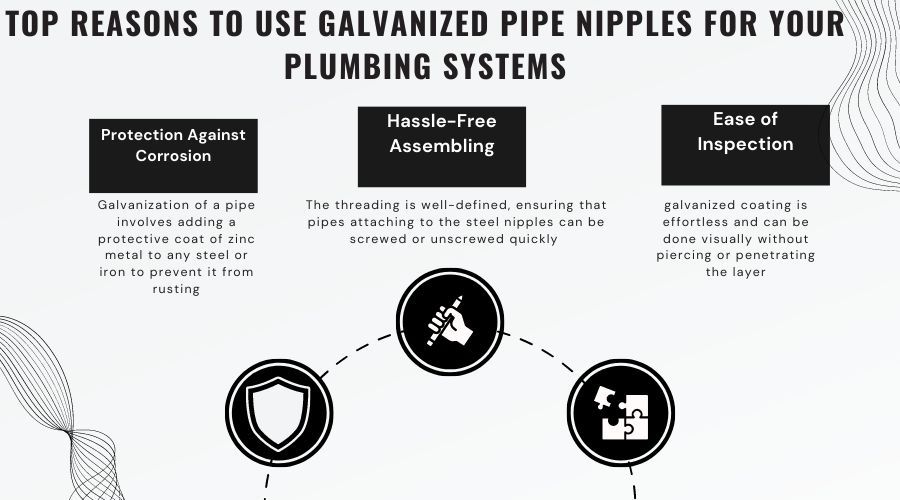

If you are looking to lengthen the life of your plumbing system, then using galvanized steel nipples is a must. Galvanized pipe fittings can withstand rusting for up to forty or fifty years. Let us look at the benefits of using galvanized pipe nipples in your plumbing network.

Over time, the iron in steel pipes reacts with oxygen and moisture in the environment to produce an iron oxide layer called rust. An additional zinc layer means a lesser chance of a reaction with iron, and the rust must corrode the zinc coating first before it gets to the steel. This slows down the process of rusting. Hence, galvanized steel pipes can last a long time before needing replacement.

The longer usage life means that maintenance costs are significantly lower for a galvanized steel plumbing system. Moreover, other pipe protection methods are costly as compared to galvanization.

A galvanized pipe's durability depends on the coated layer's thickness. Check a galvanized coating is effortless and can be done visually without piercing or penetrating the layer. The production date of the pipe nipple is visible on the pipe surface, so galvanized steel nipples are available for a fast and easy checkup if there is a problem in the plumbing system.

Top-quality galvanized steel nipples have finer threading on both ends than regular iron pipes. The threading is well-defined, ensuring that pipes attaching to the steel nipples can be screwed or unscrewed quickly and reliably. This ensures a tighter fit and makes the plumbing system leakproof.

While zinc coating is excellent for weather resistance and protection against outside elements, it is not as effective on the internal surface of the pipe. This is also because the pipe interior is constantly in contact with flowing water or liquid. This contact with moisture means the internal coating erodes faster than the external layer. When the rust eats away, the pipe is no longer leakproof, and water pressure can also break the pipe.

As soon as galvanized pipes start eroding, the uncovered metal's corrosive elements and lead may infiltrate your water supply. This can result in the accumulation of mineral deposits inside the pipes, forming a layer of plaques. Eventually, the build-up restricts the water flow in your house, causing watercolor and quality changes.